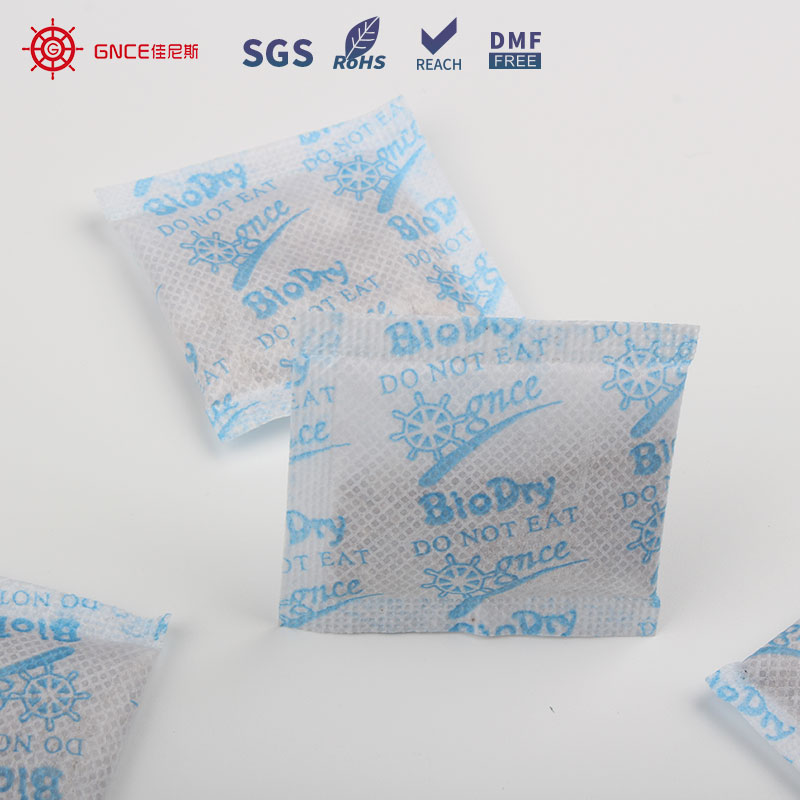

The antibacterial agent AEM5700-A05 can be used for the antibacterial processing of textiles.

Product Introduction

The antibacterial agent AEM5700-A05 can be used for the antibacterial processing of textiles. It has the advantages of strong bactericidal power, persistence and instant effect. It will give the treated substrate excellent and durable antibacterial properties, and has unique protective functions against microorganisms.

AEM5700-A05 is suitable for all types of fabrics, and can be flexibly combined with related processes and production conditions for antibacterial processing. It can avoid problems such as deterioration or discoloration of products caused by bacteria, algae, yeast, etc., and can prevent odors from occurring.

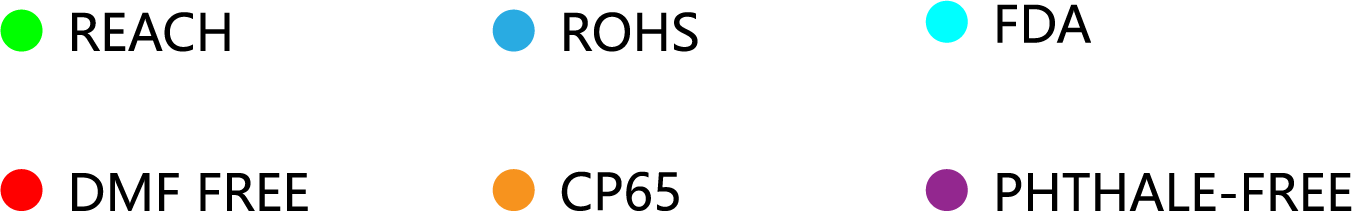

AEM5700-A05 meets relevant environmental protection requirements and has passed relevant environmental testing certifications such as Reach, Rohs.

Application Scope

◎ sports-related clothing: such as casual wear, golf wear, sweatshirts, underwear, etc.

◎ Home accessories: such as carpets, sofas, curtains, bed sheets, bedspreads, pillow cases, etc.

◎ sports equipment: such as knee pads, elbow pads, waist, etc.

◎ kitchen bathroom: such as shower curtain, bathtub, rag, etc.

Usage Method

I fabric preparation

1. For best results, when antibacterial processing is carried out, the surface of the fabric should be free of substances that are easy to fall off, and there is no staining. Therefore, wash it thoroughly before processing, otherwise no durability.

2. The fiber drop rate of the fabric must be less than or equal to 1.5%. It is recommended to test by AATCC97.

3. For the anionic processing agent, do not use the same bath processing, apply two baths separately processing, and first use AEM5700-A05 for antibacterial processing.

II Antibacterial processing method 2: When the fabric is shaped and processed

1. The concentration of antibacterial agent in the water is added to the concentration

1.1 Preparation concentration = antibacterial addition amount / fabric liquid ratio × 100%

1.2 fabric with liquid rate = (cloth weight after water absorption - dry weight of the cloth) dry weight × 100%, the weight of the cloth after water absorption is the weight of the cloth after rolling.

Note: In the antibacterial finishing of textiles, the proportion of absorbent agent reaches 3% of the weight of the fabric, and it can be washed at least 20 times.

Example: The proportion of absorbent agent reaches 3% of the weight of the cloth, that is, 3 kg of AEM5700-A05 antibacterial agent is required for 97 kg of cloth. If the fabric has a liquid

90%, the concentration of antibacterial agent in our shaped water should be 3.33%. (The concentration of antibacterial agent in the shaped water = 3% ÷ 90%, which is 3.33%. Actually should be slightly larger than this concentration)

1.3 After confirming the concentration, add 80% water first, gradually add 3.33% antibacterial agent under stirring, and continue to add the remaining 17% water. Prepared well

After the type of water, put it into the trough.

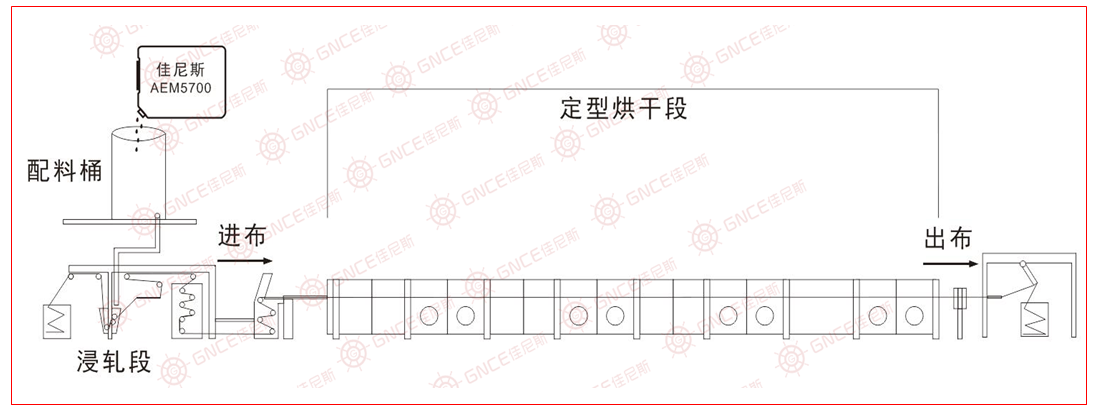

2. Antibacterial processing - using padding process

1 The fabric is immersed in a setting water to which an antibacterial agent is added.

2 Press off the excess working fluid or use dehydration.

3 Drying and baking temperature is between 120 ° C and 160 ° C, and it is kept sufficiently dry.

Reminder

1. Before using it with other additives, it is necessary to thoroughly confirm the compatibility with the compounding agent through preliminary experiments.

2. Please try to use up the prepared treatment solution within 12 hours.

3. Fabric dyeing After washing, ensure that the fabric surface is controlled at 6-8 before antibacterial treatment.

4. It is recommended not to add acid in the working fluid, and citric acid is prohibited in the production process.

5. Please do not add chelating agents, sulfur-containing additives or other materials that inactivate silver.

6. Please do not mix antibacterial agents and adjuvants under high concentration conditions.

Effect Show

-

Metal antibacterial agent AEM5700-F3

Add Wash List Details

Add Wash List Details -

Silver ion textile antibacterial agent AEM5700-A05

Add Wash List Details

Add Wash List Details -

Zinc ion antibacterial agent

Add Wash List Details

Add Wash List Details -

Silicone Antibacterial Paste AEM5700-PB

Add Wash List Details

Add Wash List Details -

Antibacterial agent AEM5700-A2

Add Wash List Details

Add Wash List Details -

PE Antibacterial Masterbatch PE 102

Add Wash List Details

Add Wash List Details