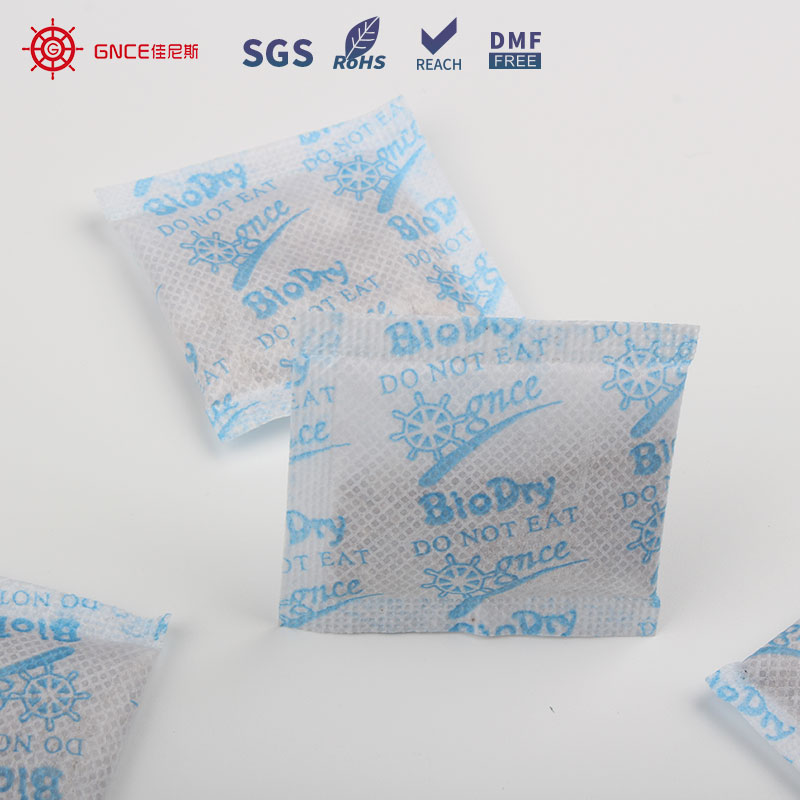

The antibacterial agent AEM5700 can be used for the antibacterial processing of textiles.

Product Introduction

The antibacterial agent AEM5700 can be used for the antibacterial processing of textiles. It has the advantages of strong bactericidal power, persistence and instant effect, can prevent the harm caused by microorganisms, improve the quality of life, improve the functionality of products.

AEM5700 is suitable for all types of fabrics. It can be widely used in a variety of production methods, flexible combination of relevant process and production conditions for antimicrobial processing. It is a non-release type treatment agent that does not leak, does not migrate. It adopts special mechanical sterilization, which does not appear to be resistant to chemicals, and can avoid problems such as deterioration or discoloration of products caused by bacteria, algae and yeast, and can prevent odor generation. It can be washed repeatedly for 10-20 times.

AEM5700 meets relevant environmental protection requirements and has passed relevant environmental testing certifications such as Reach, Rohs.

Application Scope

◎ Sports-related clothing: such as casual wear, golf wear, sweatshirts, underwear, etc.

◎ Bag products: cloth bags, medical bags.

◎ Home accessories: such as carpets, sofas, curtains, bed sheets, bedspreads, pillow cases, etc.

◎ Sports equipment: such as knee pads, elbow pads, waist, etc.

◎ Kitchen bathroom: such as shower curtain, bathtub, rag, etc.

Usage Method

I fabric preparation

1. For best results, when antibacterial processing is carried out, the surface of the fabric should be free of substances that are easy to fall off, and there is no staining. Therefore, wash it thoroughly before processing, otherwise no durability.

2. The fiber drop rate of the fabric must be less than or equal to 1.5%. It is recommended to test by AATCC97.

3. The cloth must be weakly acidic and the alkali content must be less than 0.05%. It is recommended to pass AATCC144 for testing.

4. For the anionic processing agent, do not use the same bath processing, apply two baths separately processing, and first use AEM5700 for antibacterial processing.

II Antibacterial processing method 1: directly added to the dyeing tank or processed simultaneously with other finishing processing agents

1. If it is necessary to carry out softness, hand feeling, waterproof, anti-static and anti-fouling at the same time, in order to avoid the effect of reduction, the ionicity of these finishing agents must be considered. If it is a cationic or non-ionic processing agent and can be treated in the same bath as AEM5700.

2. For anionic processing agents, this method is not applicable.

3. Before use, try it first. If there is no abnormality, it can be added directly. Generally, the addition ratio is about 1-3%, depending on the antibacterial requirements.

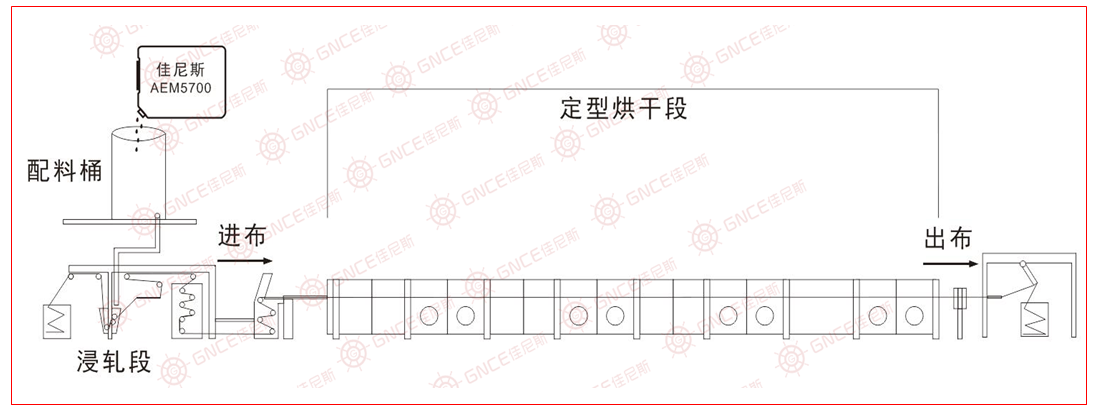

III Antibacterial processing method 2: When the fabric is shaped and processed

1. Blending of working fluid: the amount of medicament added in water

In the antibacterial finishing of textiles, we generally calculate the concentration of the absorbing agent of the fabric, and the proportion of the absorbing agent reaches 1% to 3% of the cloth weight. If the antibacterial ability of the fabric to be treated reaches 99% or more, the proportion of the absorbent agent reaches 3% of the weight of the fabric, that is, 3 kg of the AEM 5700 antibacterial agent is required for the 97 kg fabric. If the wet weight gain of the fabric is 60%, the concentration in our shaped water should be 5%. (calculated as follows)

Formula 1: Wet weight gain rate = (cloth weight after water absorption - dry weight of the cloth) dry weight of the cloth × 100%, the weight of the cloth after water absorption is the weight of the cloth after the roller is rolled

Formula 2: Absorbing agent ratio = wet weight gain rate × setting water concentration

For example, the concentration of the drug in the shaped water = 3% ÷ 60%, which is 5%, which should be slightly larger than this concentration.

2. Antibacterial processing

2.1 Dip the textile through the working fluid.

2.2 Press off the excess working fluid or use dehydration.

2.3 drying (temperature 150 °C, time 55s or so, the specific temperature, time is determined by the product and process flow).

Reminder

1. Before using it with other additives, it is necessary to thoroughly confirm the compatibility with the compounding agent through preliminary experiments.

2. Acid dyes need to be advanced fixed color, add another 5700 treatment, or please confirm the processed color changes in advance.

3. Please try to use up the prepared treatment solution within 12 hours.

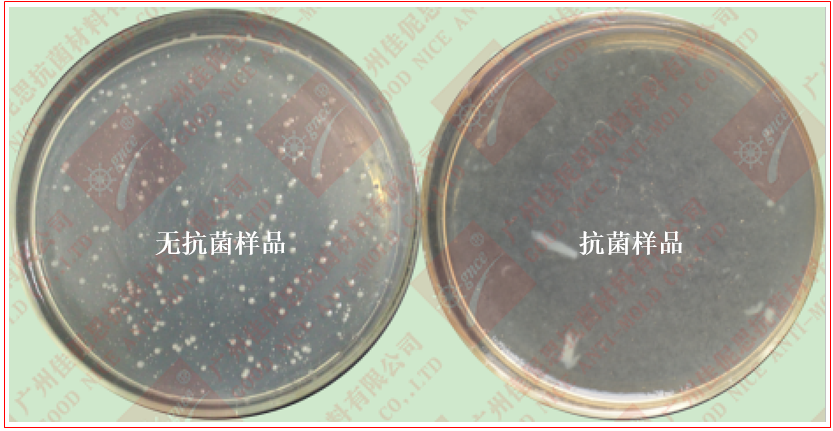

Effect Show

-

Metal antibacterial agent AEM5700-F3

Add Wash List Details

Add Wash List Details -

Silver ion textile antibacterial agent AEM5700-A05

Add Wash List Details

Add Wash List Details -

Zinc ion antibacterial agent

Add Wash List Details

Add Wash List Details -

Silicone Antibacterial Paste AEM5700-PB

Add Wash List Details

Add Wash List Details -

Antibacterial agent AEM5700-A2

Add Wash List Details

Add Wash List Details -

PE Antibacterial Masterbatch PE 102

Add Wash List Details

Add Wash List Details